About us

For over 35 years on the market manufacturing quality injection molding machines, 100% manufactured in Brazil, with exclusive support and product guarantee.

Quality, excellence and customization of machines and parts

There are more than 3,500 injection molding machines installed in Brazil and other countries. We are specialists in tailored solutions with customized options that can optimize your production. From simultaneity of movements, increasing dosing speed, changing the current cycle, among others. We certainly have the ideal option to increase your profits. Contact one of our experts and find out!

years on the market

Installed equipment

In 1980, Tsong Cherng began its activities with a small plastics processing factory called TC Plast, in the city of São Paulo – SP.

At the end of the 80s, we expanded the factory to the east side of São Paulo, in the Tatuapé neighborhood, where we started importing and selling injection molding machines from Taiwan – high quality injection molding machines at an affordable price.

In 1997, we began the expansion phase of our facilities, acquiring an area of 10,000m2 in the city of São Bernardo do Campo – SP to date.

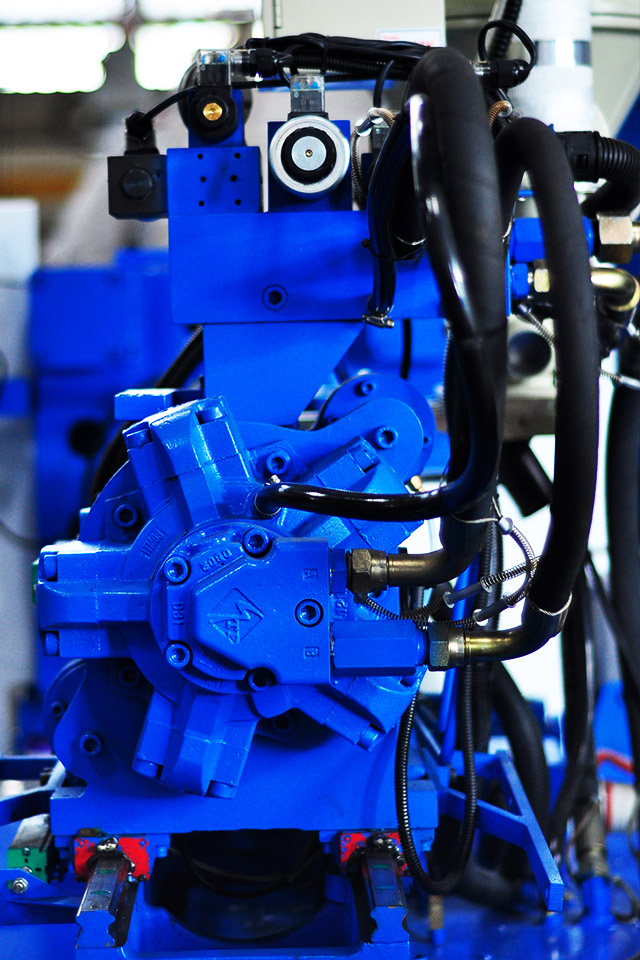

In the new facilities, we began manufacturing injection molding machines using the same top-of-the-line electrical, electronic and hydraulic components, always keeping quality first.

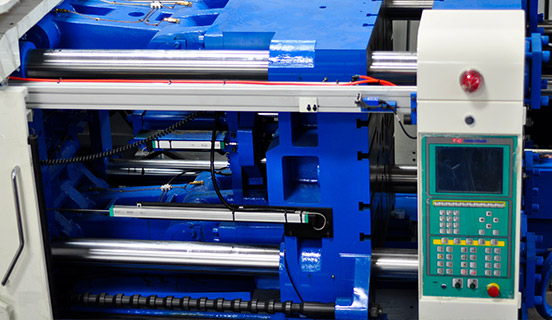

The first major launch was the TC series of injection molding machines, which had a capacity of 120 to 2200 tons of closing force, becoming a great success.

Since our founding, we have always valued quality in our equipment, guaranteeing our customers the best on the market.

Despite being a foreign company, we have been in Brazil for many years and have completely adapted to the Brazilian market.

Our new direction managed to maintain the quality standard and brought innovations to the market, giving it a younger look, offering the most advanced technology for plastic injection molding machines.

1988

Start of activities supplying injection molding machines to the Brazilian market.

1997

Launch of TC Series injection molding machines – 120 to 2200 Ton.

1999

Nitrogen injectors for rapid injection.

2003

Entry into the mold and injection molding market for PET preform manufacturing

2005

Injector with frequency inverter drive to save electricity (56% savings).

2006

Launch of EUROMAQ series injection molding machines – 75 to 2300 tons.

2007

Launch at Brasilplast – E-255 Injector with electric dosing, simultaneous opening + dosing + extraction movements and nitrogen for fast injection.

2008

Launch of the S Series injectors – Hydraulic injectors driven by a servo motor to save electricity (75% savings).

2009

Launch of the Electric Series injectors – 100% Electric drive (90% savings).

2010

Launch of the FIT Series injection molding machines – Lower investment cost without losing Quality.

2013

Launch at Brasilplast of the ES-1100 DP injection molding machine with 2-plate closure – EUROMAQ DP.

2015

Launch at Feiplastic of the large-scale PET preform production cell – TC PET Series.

2017

Launch of EUROMAQ ES-305 HYBRID injection molding machine – Hybrid drive injection molding machine for PET preforms with simultaneous movements providing a 30% increase in productivity with electricity savings.

2018

FIT-360BT injector with rapid injection system driven by a servo motor 300mm/sec.

2021

Rebranding: New visual identity and strategic positioning.