Injecting Profits

Versatility for your business.

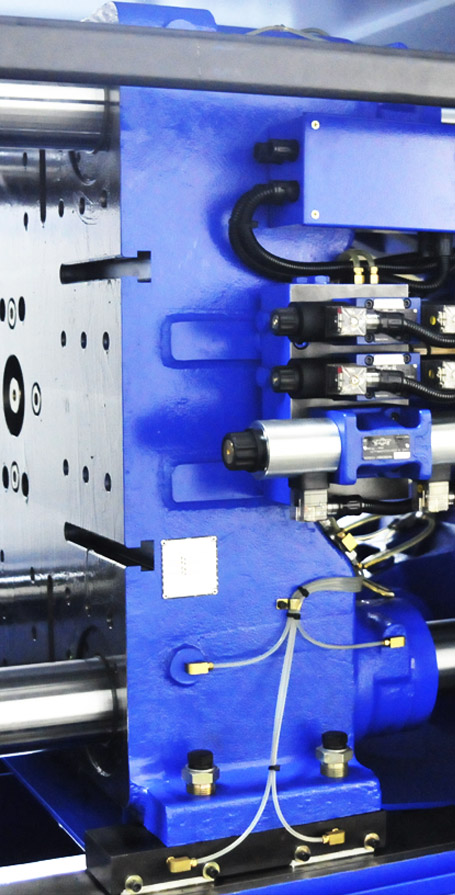

High performance for your business.

Molds Pet Preforms.

Peripherals and Spare parts.

How to choose a perfect Plastic Injection Machine for your business?

Are you thinking about buying a new plastic injection molding machine? Be sure to read this text.

01. Research and Planning

Firstly, you need to plan and do a lot of research before buying an injector. Take into account the structure and seriousness of the supplier company, the quality of the equipment, such as: technical details, weight, components used, technical support and stock of spare parts.

02. Sizes and Models

Knowing how to size which model best fits your needs is the most important point so that the chosen machine achieves a return on your investment in less time.

Count on Tsong Cherng’s consultancy to find out which machine is ideal for your business. The experience and knowledge over all these years is the security you need.

03. Savings and Increased Productivity

Finally, the industry’s challenge is to increasingly combine two words that seem to be opposites: Economy x Increased Productivity. Only with a modern machine with higher speed and an energy saving system is it possible to increase productivity while reducing electricity consumption.

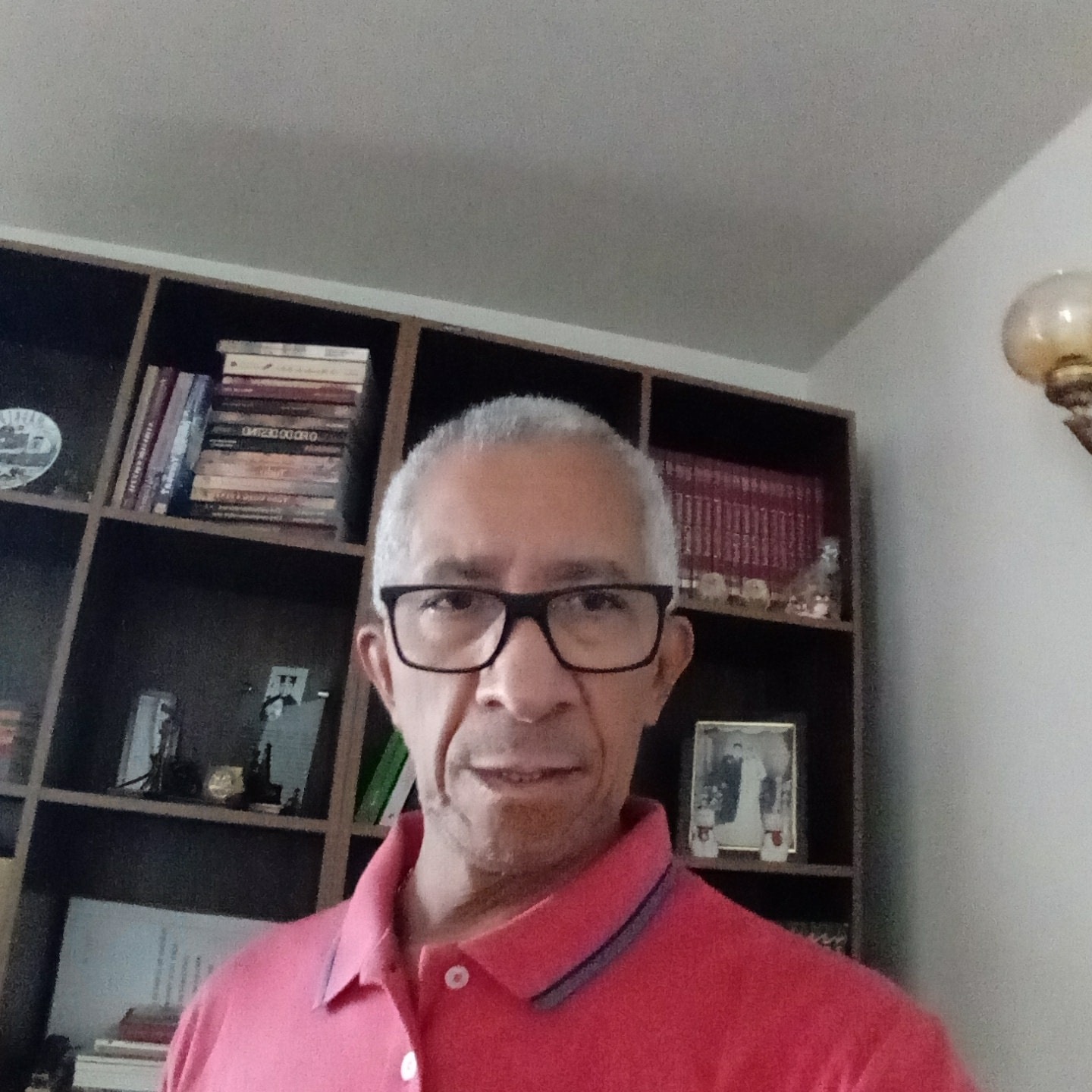

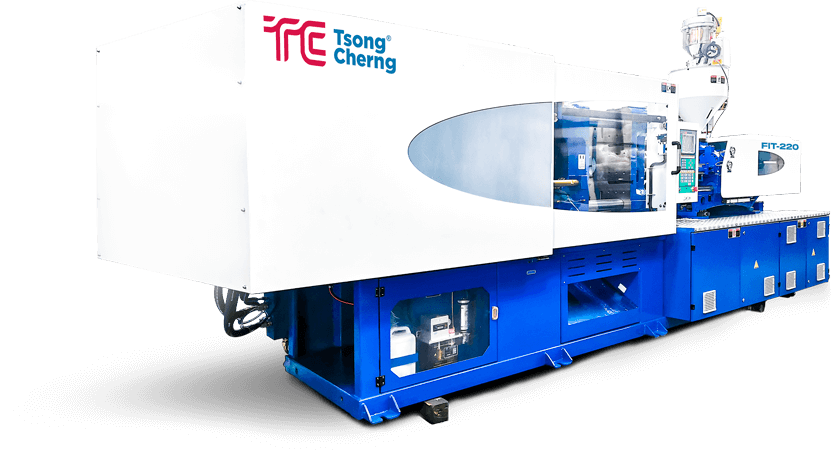

Our products

We have been in the Brazilian market for over 35 years providing standard or custom injection molding machines, always prioritizing quality, after-sales service and customer satisfaction.We are specialists in tailored solutions with customized options that can optimize your production. From simultaneous movement, increasing dosing speed, changing the current cycle, among others. We certainly have the ideal option to increase your profits. Consult!

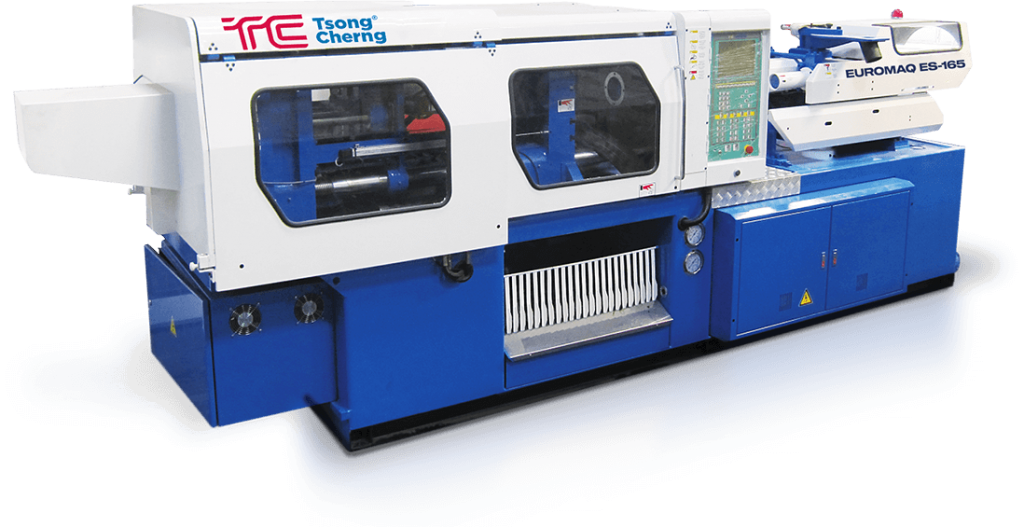

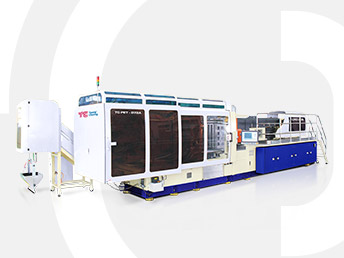

Série

TC PET

High performance on a large scale for your business

TCPET D32 to TCPET D96B

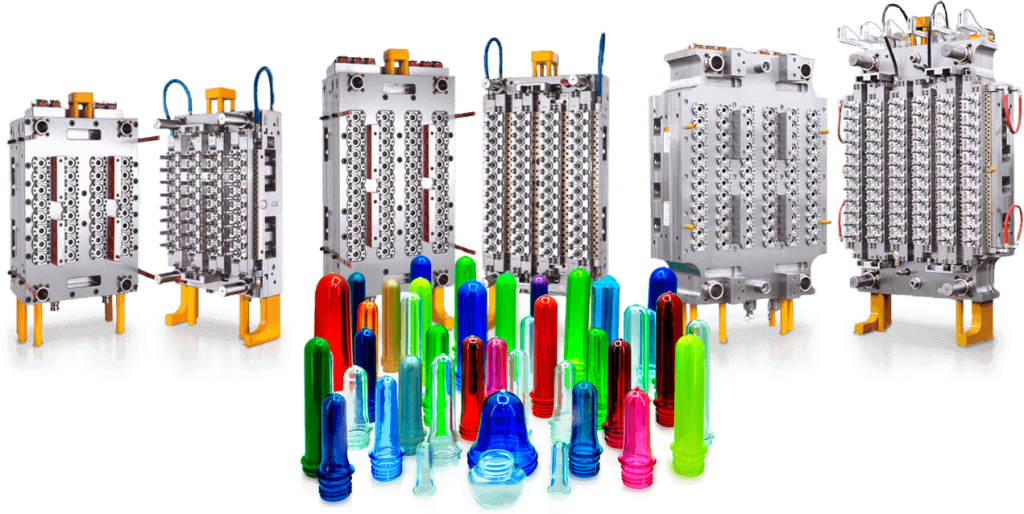

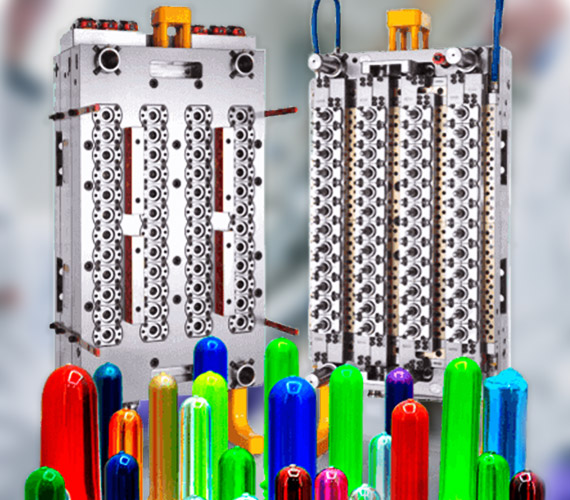

Molds for manufacturing Pet Preforms

We provide plastic injection molds for various products as per your sample or design.

Molds made with first-rate certified materials, which guarantees reliability and durability of the tool.

We have our own tooling to guarantee all the necessary support for development and preventive or corrective maintenance and a large stock of original parts for molds manufactured by us and also for the main brands on the world market.

Peripherals

Automate and improve the production process of your injection molding machine. Dryer hoppers from models HD-50 to HD-560, Automatic Feeders BC-4, TA-6 and TA-8, Crusher Mills up to 100CV and Material Mixers from 3CV to 10CV. Peripherals help with the productivity and quality of your injected parts, as they optimize production time, increasing your profits. Consult the page and have access to all technical specifications. We will certainly have the model suited to your needs.

About Us

Discover our history over more than 35 years of excellence and machine sales.

Our support

The sale of a machine is not finalized immediately after the technical delivery of the equipment.

Where are we

Avenida do Taboão, 3085

Vila Santa Luzia

São Bernardo do Campo – SP

CEP: 09656-000

Talk to us today

Our customer service is always open to receive any queries or feedback. Feel free to send us a message by email or via WhatsApp.

SEND BY WHATSAPP

+55 11 4361-2100

We have spare parts!

We have a large stock of original parts for replacement, which guarantees us record time on the market.

What they say about us

We greatly value the quality of our products and also the satisfaction of our customers.