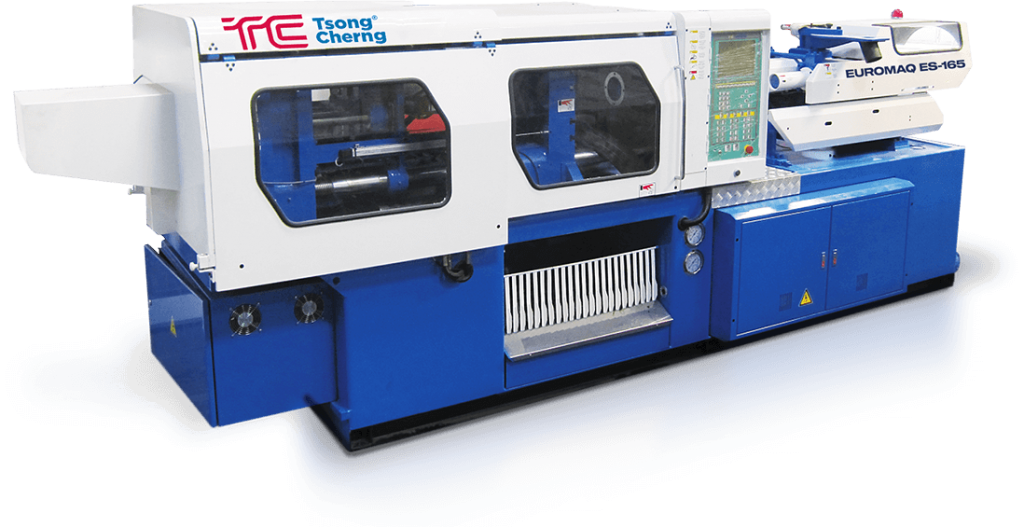

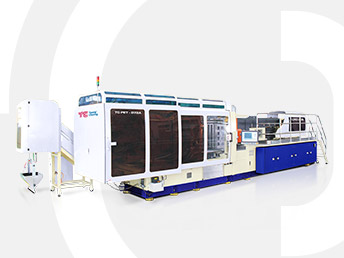

Euromaq

Versatility and Flexibility for your business.

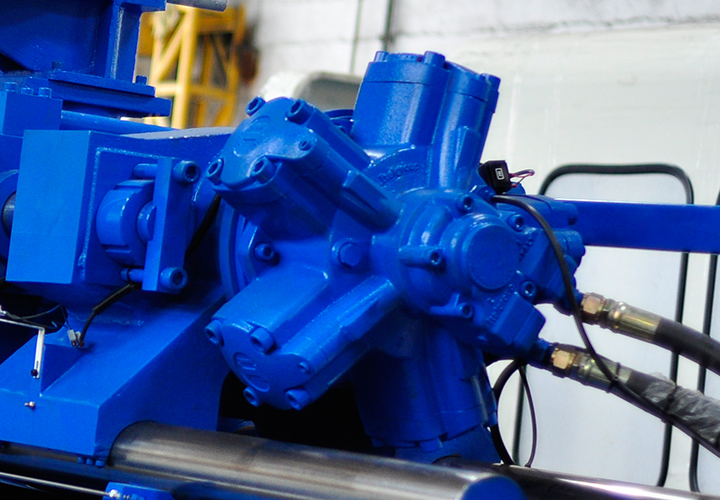

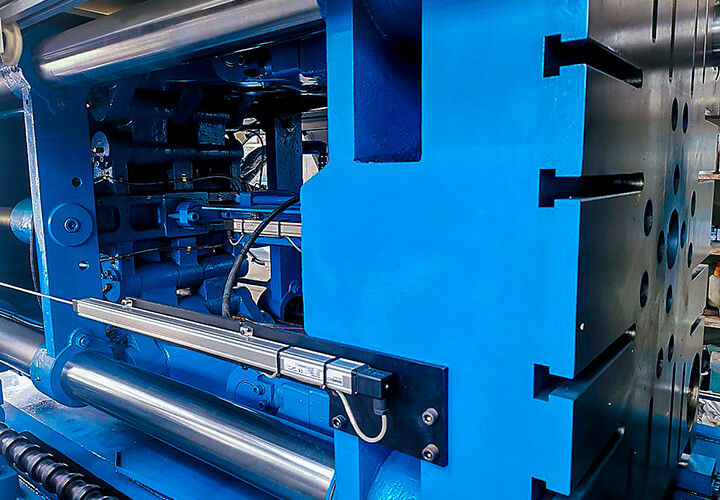

Rexroth Hydraulic Directional Valves

Intermot Dosing Motor

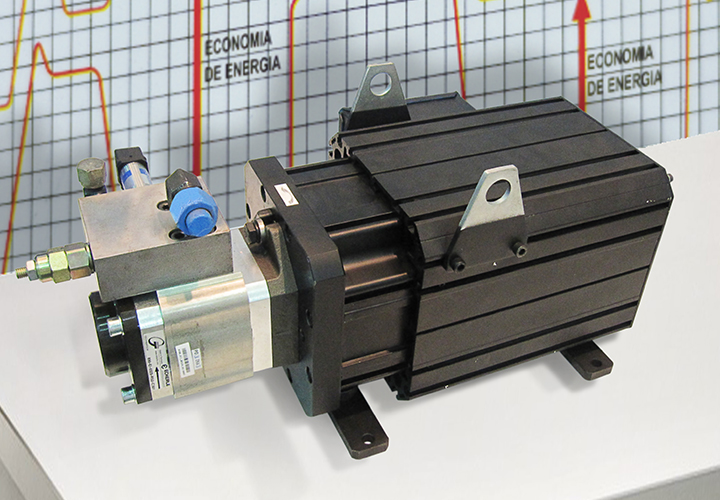

Servo Motor

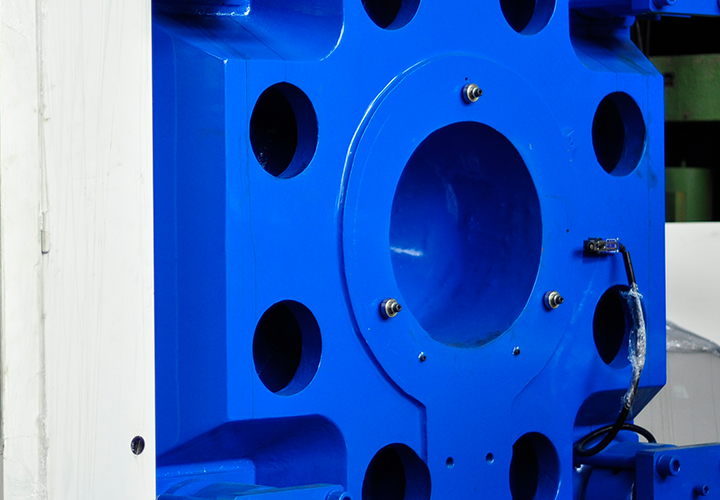

Fixed Plate

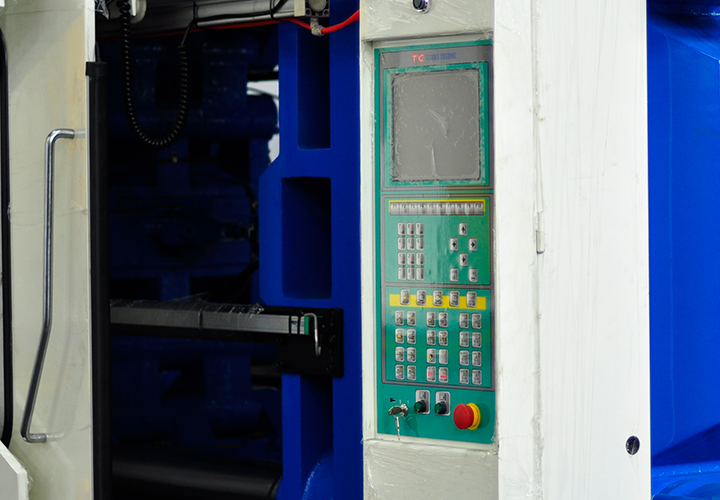

Techmation Panel

Robust Closure Set

Specifications

- TECHMATION C7000 controller (Taiwan); High speed in simultaneous control of several movements

- Easy-to-operate panel with 10′ TFT color LCD screen

- 200 internal memory positions for pattern recording

- USB port for recording mold parameters and screen images

- Robot interface – Euromap 12 or 67

- Photocell sensor for confirmation of parts output

- PID temperature control for each laminating cylinder zone with preheating program

- Monitoring quality control and quantity of parts

- Safety system: Electrical, mechanical and hydraulic (in accordance with standard NR-12)

- Closing plates in GGG 60 steel with “T” slot clamp fixation

- Scissor-type closing mechanism with 5 pivot points

- Movement control through precision linear transducer

- 5 Stages of mold closing and opening

- Ultra-quick shut-off valve

- Lateral hydraulic tap system with different control modes

- Hydraulic extractor with various functions controlled using a precision linear transducer

- Puller recoil sensor for mold protection

- Automatic lubrication system

- Automatic mold height adjustment

- 4 Stages of pneumatic extraction

- Injection system controlled using a precision linear transducer, guarantees excellent precision and repeatability in the process

- Injection driven by double hydraulic piston

- Six injection and five dosing stages with independent pressure, speed and position adjustments

- Diversified decompression mode: before or after dosing with position, pressure and speed adjustment

- Dosage delay

- Injection with intrusion capability

- Back pressure control

- Threads with specific L/D for all types of plastic resins

- Nitrogen accumulator for ultra-fast injection

- Twin Loop System – Simultaneous opening + extraction movement

- Three Loop System – Simultaneous opening + extraction + dosing movement

- Hybrid System – Servo Electric dosing motor: provides precision, 20% electricity savings and simultaneous opening + dosing movements

- Bimetallic injection thread and cylinder

- Hydraulic pump drive by servo motor

- Closed Loop system and savings of up to 75% of electrical energy

Datasheet

Choose the model that best suits your product. All data presented below are standard configurations, with the possibility of customization. Talk to our consultants and increase production capacity by adapting the machine’s specifications, according to your needs.

Want to compare the data? Download our PDF catalog now.

Check out our other machines

Série

TC PET

High performance on a large scale for your business

TCPET D32 to TCPET D96B